3D Printing for Pre-Surgical Planning

3-D printing capabilities have revolutionized the surgical world by enabling pre-surgical planning for limb deformity corrections, facilitating metal plate pre-contouring, and helping your clients understand the difficulty and complexity of the surgical correction planned.

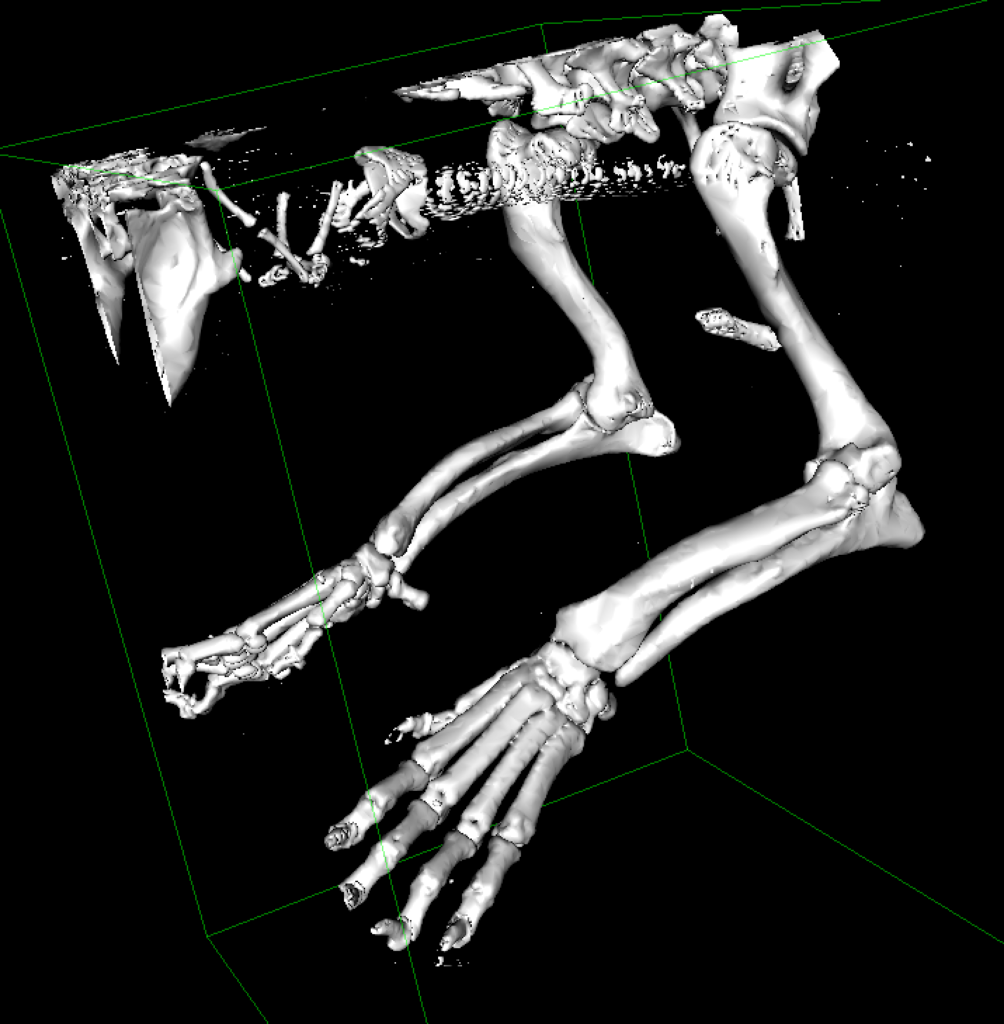

Using medical imaging such as CT scans, we can create a detailed 3D model of a patient’s bone or bones. This model can be used to plan and practice the surgery, allowing the surgeon to get a better understanding of the anatomy and the best approach to the procedure, which as a result, has shown to significantly reduce intra-operative and anesthetic time, thus reducing infection rates and improving patient outcomes.

The 3D models typically ordered are for limb deformity corrections in both the thoracic and pelvic limbs, however, any part of the skeleton can be printed including the vertebrae and skull. If you are interested in this 3D printing service, please download and fill out the following form detailing your patient’s specific needs and email it to [email protected]. She will then contact you and guide you through the next steps.

How does it work?

Simply download and send me the folder of the DICOM images from the CT scan you performed on your patient. Using advanced reconstruction software, a digital model of the bones is created.

- Please try to avoid including any metal components in the acquisition window at the time of the CT scan, as this creates a lot of artifact defects in the digital reconstruction. If there is an existing metal implant in the area you need a model of, the 3D print can still be done but additional fees will apply depending on the amount of manual reconstruction the model requires (depending on the severity of the scatter and artifact in the CT scan images).

After the digital anatomical model created in step 1 is oriented in a position that will optimize the strength of the final product, and support structures are generated, the final design is sent to the 3D printer for printing. Most models are printed in PLA-ST, a stronger version of non-toxic plastic. Other plastic options are available, if needed. After printing, the models are carefully separated from their supports, the surface is lightly sanded and examined for imperfections. If printing errors or defects occur, adjustments are made and a new model is printed. The models are then packaged and delivered to the referral hospital, directly to the lead operating surgeon.

The 3D printed Models are made using PLA-ST plastic, which is specifically designed to withstand drilling and cutting using an oscillating surgical saw. Some degree of melting plastic is unavoidable due to the heat produced from the drill / saw, so the saw blade and drill bits used will no longer be suitable for intra-operative use, however, the integrity of the plastic model should remain intact.

After cutting the plastic bones, you can use cross-pinning with K-wires or hot glue from a craft glue-gun to adhere the cut ends together. This will allow you to maintain the new reduced orientation and re-measure the joint orientation lines to ensure your calculations corrected the deformity in question. Please note that several adjustments to these calculated angles are often needed in cases of angular deformities with greater than 15 degrees of torsion. Additional prints can be purchased individually, even at a later date, digital models will be kept for 5 years after their order date.

How much does it cost?

The cost for modeling one area, printing 2 models, and delivery to your hospital is $250 for small models (150x150x150mm) or $300 for large models (250x250x330mm). Additional models cost $50 and $75 respectively. Please note taxes are not included. A deposit of 100$ is required prior to starting the process, the rest of the payment is due upon delivery.

Every order comes with one additional hollow model which is not designed for cutting, and can be used as a pre-operative reference.

How long does it take?

Please expect a production delay of about 2 to 3 weeks after submission of the DICOM images from the scan. For time-sensitive cases, your 3D models can also be produced and delivered with a 1 week delay at an additional fee.